همه محصولات

-

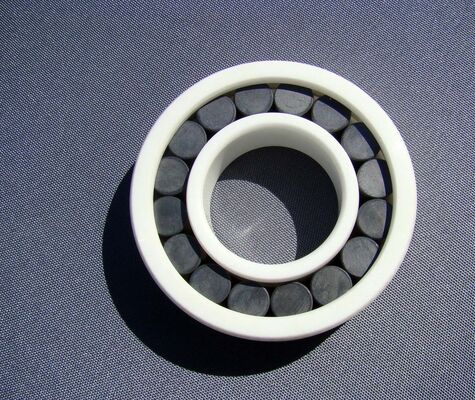

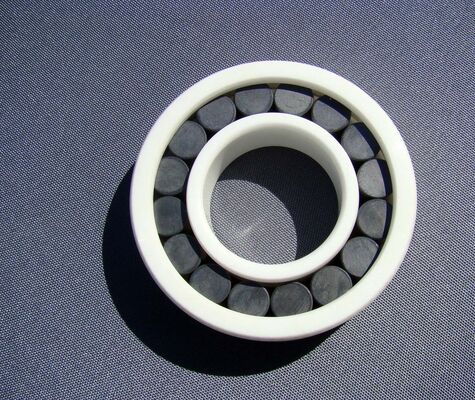

بلبرینگ سرامیکی

-

608 بلبرینگ سرامیکی

-

بلبرینگ سرامیکی هیبریدی

-

محموله های کربید سیلیکون

-

بلبرینگ کشویی سرامیکی

-

رولبرینگ سرامیکی

-

بلبرینگ سرامیکی تراست

-

سرامیک ساختاری پیشرفته

-

توپ سیلیکون نیترید

-

توپ سیلیکون کاربید

-

توپ سرامیکی زیرکونیا

-

بلبرینگ سیلیکون کاربید

-

بلبرینگ نیترید سیلیکون

-

بلبرینگ سرامیکی زیرکونیا

-

آب بندی مکانیکی

-

روبرتابلبرینگ های سرامیکی آنها از دقت بالا، کیفیت خوب و ارزان هستند. ما چندین سال همکاری داریم.

روبرتابلبرینگ های سرامیکی آنها از دقت بالا، کیفیت خوب و ارزان هستند. ما چندین سال همکاری داریم. -

اولگا واینبرگاین شرکت سال ها تامین کننده قابل اعتماد و حرفه ای بلبرینگ های سرامیکی ما است، بلبرینگ های سرامیکی آنها که در پمپ ما استفاده می شود کیفیت خوبی دارند.

اولگا واینبرگاین شرکت سال ها تامین کننده قابل اعتماد و حرفه ای بلبرینگ های سرامیکی ما است، بلبرینگ های سرامیکی آنها که در پمپ ما استفاده می شود کیفیت خوبی دارند.

تماس با شخص :

Cooper wang

شماره تلفن :

86 15801087509

بلبرینگ های غلتکی استوانه ای سرامیکی تک ردیفه با مواد Si3N4 و قفس PEEK برای مقاومت در برابر دمای بالا

جزئیات محصول

| نام | غلتک تک ردیفه سرامیکی | مواد مسابقه | نیترید سیلیکون یا کاربید سیلیکون یا زیرکونیا |

|---|---|---|---|

| مواد غلتکی | نیترید سیلیکون یا کاربید سیلیکون یا زیرکونیا | ماده قفس | Peek//PFA |

| مدل | سری NU205/NU206 | پاراگ | فوم+جعبه کارتوم |

| برجسته کردن | غلتک استوانه ای سرامیکی Si3N4,رولبرینگ سرامیکی SSiC,بلبرینگ تک ردیفی ZrO2,SSiC Ceramic Roller Bearings,ZrO2 Single Row Bearings |

||

توضیحات محصول

اسکناس های رولر سیلندر سرامیکی یک ردیف

اسکناس های رولر تک ردیف سرامیکی با عملکرد بالا که از مواد سرامیکی پیشرفته برای کاربردهای صنعتی سخت ساخته شده اند.

مشخصات مواد

خلاصه ی محصول

ما طیف گسترده ای از لاکن های سلنری سرامیکی تک ردیف را تولید می کنیم که متناسب با نیازهای خاص شما هستند.لوله های ما برای عملکرد برتر در محیط های چالش برانگیز طراحی شده اند.

داده های مرجع فنی

مشخصات دقیق و داده های عملکردی برای سری بالبر های سلندرال سرامیکی ما.

چرا انتخاب مالوله های سرامیکی استوانه ای یک ردیف Si3N4 SSiC ZrO2

تخصص حرفه ای

تحت مارک های ZXSQ و CSQ فعالیت می کنیم، ما یازده اختراع مدل مفید را داریم و یک تیم حرفه ای را برای ارائه راه حل های حامل با کیفیت بالا که با مشخصات مشتری متناسب است، حفظ می کنیم.

با بیش از ۴۰ سال تجربه از سال ۱۹۸۲، ما به طور مداوم تحقیقات، تکنیک های پردازش و بهبود تجهیزات،خود را به عنوان یک شرکت پیشرو در صنعت لوله های سرامیکی چین تاسیس می کنیم.

ظرفیت تولید

Our facility features fully automated grinding and assembly production lines capable of producing 3 million sets annually of various specifications including 608-2PS and 608-2RS with P5 and P4 precision levels.

ما از تجهیزات سوخاری پیشرو در صنعت استفاده می کنیم، از جمله کوره های سوخاری ایزواستاتیک گرم وارد شده از ABB سوئد، که باعث می شود دمای سوخاری محصول بیش از 2000 درجه سانتیگراد باشد.

پرسش های مکرر

ما کی هستیم؟

ما کارخانه ای در پکن چین هستیم که بیش از ۴۰ سال تجربه در تولید و فروش ناقل سرامیکی داریم.ما روابط همکاری با شرکت های داخلی و بین المللی زیادی داریم.

چطور می توانیم کیفیت را تضمین کنیم؟

ما قبل از تولید انبوه نمونه تولید می کنیم و به سختی به الزامات مشتری و مقررات تولید پایبند هستیم.بازرسی جامع با استفاده از تجهیزات دقیق و بسته بندی ایمن با حفاظت از فوم و کارتون کیفیت محصول را تضمین می کند.

از ما چي مي توني بخري؟

در حال حاضر، در حال حاضر، در حال ساخت و ساز است که در حال ساخت و ساز است.

چرا باید از ما بخری نه از تامین کننده های دیگه؟

به عنوان یک شرکت صنعتی و تجاری یکپارچه با سه کارخانه، ما از تجهیزات مدرن تولید و بازرسی استفاده می کنیم تا زمان های تحویل برتر و کیفیت محصول را تضمین کنیم.

ما چه خدماتی میتونیم انجام بدیم؟

ما محصولات با کیفیت بالا و خدمات سفارشی سازی جامع متناسب با نیازهای کاربر را ارائه می دهیم. نمونه محصولات برای تایید مشتری در دسترس است.

با ما تماس بگیرید

ما محصولات محور برتر را عرضه می کنیم و از سوالات شما استقبال می کنیم. به عنوان یک شرکت محور حرفه ای متخصص در تحقیق، توسعه، تولید، فروش و خدمات،ما با دقت و دقت از مواد خام با کیفیت بالا استفاده می کنیم.

ما نیازهای مشتری را در اولویت قرار می دهیم و متعهد به ارائه محصولات با کیفیت و خدمات جامع پس از فروش هستیم. امروز با ما تماس بگیرید تا فرصت های همکاری بالقوه را مورد بحث قرار دهید!

امتیازها و بررسیها

محصولات توصیه شده

امتیاز کلی

بررسی اجمالی امتیاز

توزیع تمام رتبهبندیها به شرح زیر است.تمام بررسی ها