-

بلبرینگ سرامیکی

-

608 بلبرینگ سرامیکی

-

بلبرینگ سرامیکی هیبریدی

-

محموله های کربید سیلیکون

-

بلبرینگ کشویی سرامیکی

-

رولبرینگ سرامیکی

-

بلبرینگ سرامیکی تراست

-

سرامیک ساختاری پیشرفته

-

توپ سیلیکون نیترید

-

توپ سیلیکون کاربید

-

توپ سرامیکی زیرکونیا

-

بلبرینگ سیلیکون کاربید

-

بلبرینگ نیترید سیلیکون

-

بلبرینگ سرامیکی زیرکونیا

-

آب بندی مکانیکی

-

روبرتابلبرینگ های سرامیکی آنها از دقت بالا، کیفیت خوب و ارزان هستند. ما چندین سال همکاری داریم.

روبرتابلبرینگ های سرامیکی آنها از دقت بالا، کیفیت خوب و ارزان هستند. ما چندین سال همکاری داریم. -

اولگا واینبرگاین شرکت سال ها تامین کننده قابل اعتماد و حرفه ای بلبرینگ های سرامیکی ما است، بلبرینگ های سرامیکی آنها که در پمپ ما استفاده می شود کیفیت خوبی دارند.

اولگا واینبرگاین شرکت سال ها تامین کننده قابل اعتماد و حرفه ای بلبرینگ های سرامیکی ما است، بلبرینگ های سرامیکی آنها که در پمپ ما استفاده می شود کیفیت خوبی دارند.

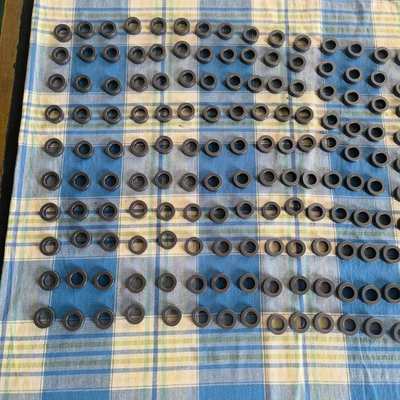

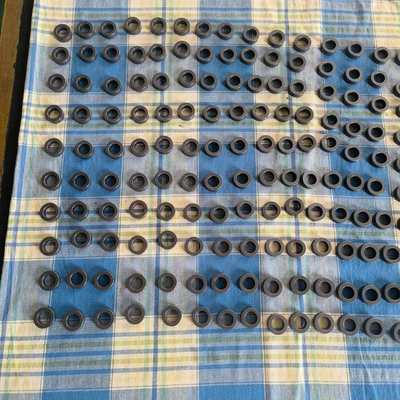

Customized SSIC Sliding Bearing Sleeve

برای نمونه و کوپن رایگان با من تماس بگیرید.

واتس اپ:0086 18588475571

ویچت: 0086 18588475571

اسکایپ: sales10@aixton.com

اگر نگرانی دارید، ما به صورت آنلاین 24 ساعته راهنمایی می کنیم.

x| نام | بلبرینگ آستین کشویی | مادی | کاربید سیلیکون متخلخل بدون فشار |

|---|---|---|---|

| دسته | بلبرینگ کشویی | اندازه | مطابق نقشه ها سفارشی شده است |

| کیفیت | با دقت بالا ، عمر طولانی ، OEM Serive | مقاومت در برابر خوردگی | عالی |

| اصطکاک | کم | دوام | عالی |

| استفاده کردن | انواع پمپ ها | بسته بندی کردن | فوم+جعبه کارتن |

| برجسته کردن | 2800 HV5 hardness SSIC Sliding Bearing,410 GPa elastic modulus Ceramic Sliding Bearing,Pressureless sintered silicon carbide Sliding Bearing Sleeve,410 GPa elastic modulus Ceramic Sliding Bearing,Pressureless sintered silicon carbide Sliding Bearing Sleeve |

||

Silicon carbide sleeves serve as high-performance plain bearings, primarily utilized in shield pumps and magnetic pumps for fluid transfer applications. These components are also adaptable to various other industrial systems requiring exceptional wear resistance and thermal stability.

Silicon carbide ceramic demonstrates exceptional properties:

- Mechanical Performance: High strength, extreme hardness, and superior elastic modulus

- Thermal Characteristics: Excellent thermal conductivity coupled with low expansion coefficient

- Specialized Attributes: Outstanding specific stiffness and precision machinability

Key properties of pressureless sintered silicon carbide:

| Max Temperature | up to 1650℃ |

| Density | 3.15-3.18 g/cm3 |

| Thermal Expansion | 4.0 (10-6/℃) |

| Thermal Conductivity | 120 W/m°K |

| Hardness | 2800 HV5 |

| Elastic Modulus | 410GPa |

| Chemical Stability | Superior resistance to acid and alkali corrosion (including hydrofluoric acid) |

- Chemical & Petrochemical Industry

- Media transfer pumps: Used in seal-less pumps (canned motor pumps, magnetic drive pumps) for corrosive fluids (acids, alkalis, high-salinity solutions)

- Reactor agitator shaft support: Resistant to high-temperature, high-pressure corrosive environments

- Semiconductor & Electronics Manufacturing

- Lithography machine motion stages: Ultra-low thermal expansion ensures nanometer positioning accuracy

- Vacuum robot arm bearings: Non-magnetic, particle-free operation

- Heavy Machinery

- Machine tool spindles: Reduces friction for higher machining accuracy

- Mining equipment wear parts: Resists slurry abrasion

Our company logo is ZXSQ and CSQ, and possesses eleven invention patents for utility models. The company now has a high-quality professional team consisting of dozens of members, to provide you with high-quality and perfect service, according to customer requirements to order a variety of bearing products.

Since 1982 we have accumulated abundant experience in production over more than 40 years, devoting ourselves whole-heartedly to the research and development of ceramic bearing material, our processing technique and improvement of our equipment.

Having undergone several evolutions and transformations, our company has now become the leading enterprise in China's domestic market in the fields of ceramic bearing and ceramic material products.

We operate a fully automatic grinding and assembling production line for ceramic bearings, with an annual output of 3 million sets of 608-2PS, 608-2RS and other specifications of P5 and P4 precision levels. Our company is equipped with rolling bearing 608 automatic production line, specializing in the production of various types of rolling bearings and ceramic balls, ceramic rollers.

Our firing equipment and technology lead the industry. We possess the most high-end equipment in the field of domestic industrial ceramics production, including a hot isostatic sintering furnace (HIP) imported from ABB Sweden. Our product firing temperature has been raised to more than 2000℃.

A: We are a factory in Beijing, China. We have been producing and selling ceramic bearings for more than 40 years. We have established friendly cooperative relations with many domestic and foreign companies.

A: We always produce samples before mass production, and produce in strict accordance with customer requirements and production regulations. After production, we use inspection equipment for precise product verification, and our packaging includes double protection with foam and cartons to ensure product quality.

A: Ceramic deep groove ball bearings, ceramic angular contact ball bearings, hybrid ceramic ball bearings, ceramic linear bearings, and all kinds of ceramic balls.

A: We are an industry and trade integrated company with three factories, equipped with modern production and inspection equipment, enabling us to provide better delivery schedules and superior product quality.

A: We provide high quality products and customized services, which can be fully tailored to user needs. We can provide samples for customer confirmation.

We supply high quality bearings. If you need to purchase or inquire about pricing, please contact us. We are a professional bearing company integrating research and development, production, sales, and service, providing bearing products and related technical services. We select high quality raw materials and carefully manufacture each set of bearings.

We adhere to customer demand as our guidance, striving to provide quality products and after-sales service, creating value for customers as their trusted partner. We welcome discussions about potential cooperation!

امتیاز کلی

بررسی اجمالی امتیاز

توزیع تمام رتبهبندیها به شرح زیر است.تمام بررسی ها